Bottom Line Up Front: Did you know direct-to-film transfers have grown in popularity recently due to their versatility and ability to accommodate short runs? Learn how and why this printing method might be a good option for your shop.

Running a successful print shop isn’t just about a conveyor packed with printed shirts or a job board full of customer orders. It’s also about shifting gears when the seasons change so you’re ready to create artwork and print customized merchandise for your customers’ timely event.

That seasonality includes times like the holiday season, when there’s a demand for Christmas, Hanukkah, and Thanksgiving merch, and other similarly themed products. Back-to-school season is also typically a time when customers need printed merchandise in a short window, and shops need to be flexible.

And there are probably other times when your shop has a short timeframe to capitalize on a timely event, maybe a local parade, 5K, festival, or other annual event.

These short but busy printing periods mean your shop needs to be ready for high-demand orders that are often in smaller quantities.

So, what’s the key to keeping up with a high volume of low-quantity orders?

The short answer is printing methods that don’t take your team a lot of time to set up and decoration disciplines that allow you to offer all types of apparel and promotional goods for easy, profitable bundle packages.

While there are a few applications like sublimation and direct-to-garment that can fill this need, let’s focus on direct-to-film (DTF) transfers for this scenario. You might’ve already heard about this technology, as it’s been all the buzz at recent trade shows and is a popular printing method for many shops already.

Why are DTF transfers so popular?

If you want a complete breakdown, check out this blog, where we discuss the process and why it’s so beneficial to shops. In essence, DTF is ideal for short runs because it works on a comprehensive set of soft and hard goods, and you can print detailed, multicolor designs in a single pass.

Finding the Right Fit

DTF printing has recently enjoyed significant popularity, but how do you know if it’s the ideal fit for your business?

If you’re looking to bolster the short turnaround and low-volume order side of your business, it can be a great option. Once artwork is finalized and printed onto a PET film, it’s a relatively quick process of adhering the transfer to a product with adhesive powder and a heat press (or curing oven).

It’s a feasible option when you have a customer who needs a 20-30 piece order on a short turnaround. That kind of request would typically be a headache on other machines like a screen-printing press. And unlike DTG, which also is excellent for short runs, there’s no pretreatment process, reducing prep time.

Plus, the multi-color design capability means you can charge a premium price based on the quality of the artwork. You aren’t spending as much on the labor clock, and you’re knocking out a short order that will make your customers happy and help grow word-of-mouth reputation. It’s a win-win for both parties.

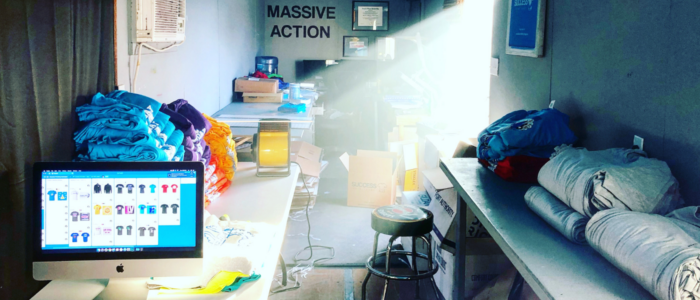

Want some inspiration? Check out this shop to get a real-life picture of how DTF printing works in action. They’ve had a lot of success with that side of their business, giving them extra time to prototype future designs for customers.

Upfront Costs

The actual dollar amount of setting up your shop for DTF printing varies depending on the volume you’re interested in printing, and the type of equipment and supplies you opt in on. Here are some rough estimates:

- DTF Printer: You’ll need a printer to print your transfers, and that investment can range anywhere from roughly $1,000 for smaller, entry-level printers to upwards of $10,000 for wide-format, industrial DTF printers. This investment is probably the best one to visit a tradeshow to explore or chat with a manufacturer’s rep so you can assess what’ll fit your needs best.

- Heat Press: Chances are your shop already owns a heat press if you’re offering other decoration methods, so you may not need to purchase a press. If you’re intent on running DTF as an entirely separate line in your shop, getting an independent heat press may make sense. Here again, you can spend as little as a few hundred to thousands of dollars, depending on the size and quality of the heat press you want.

- DTF Ink: You’ll need direct-to-film ink to print your transfers, which come in cartridges and pouches, depending on the model printer you use.

- PET Film: PET film comes in rolls and cut sheets, and runs from as little as about $20 to upwards of $100, depending on the footage, width, and whether or not you’re using sheets or rolls.

- DTF Adhesive Powder: The hot-melt adhesive powder for DTF transfers starts around $20-30, depending on the volume of the bag you purchase.

Along with physical equipment, you’ll need proper RIP software to finalize artwork for DTF transfers, particularly one capable of white and CMYK colors. Much like a heat press, this may already be something your shop uses for other jobs.

Here’s some more information to consider with your upfront costs:

Financial Opportunity

You might also be thinking, “but where’s the money in this?” That’s a fair question since DTF printing is an investment, just like buying another screen-printing press, embroidery machine, DTG printer, or any other key piece of shop equipment. Consider these factors:

It opens the door to new business: If you’re a high-volume shop that mainly does screen-printing orders, DTF opens the doors to a whole other subset of customers. You can still stay on top of those big orders while offering small, customized jobs and price them out to make them worth your time.

You can price it for profitability: While the initial investment of a printer can be costly, some of the other DTF supplies aren’t as steep when you factor in the total print cost. Some manufacturers estimate the cost breakdown of products like PET film at 50 cents per print. Depending on volume and print size, ink and powder can break down to less than $1 per print. That means you and your team can charge a premium for this service.

It’s part of a growing market: The pandemic may have thrown a monkey-wrench in supply chains and wreaked havoc on print shops. But the decorated apparel industry is growing. As of May 2022, some experts estimate the market will grow to over $70 billion by 2030. Adding a service like direct-to-film transfers to your lineup only stands to help you stay ahead of the competition.

If you want some deeper discussion on how DTF printing can boost your bottom line, take a look at this recent chat with a few industry experts:

Using the Right Tools

Here’s the exciting news; your shop can combine the power of DTF printing with a few industry-leading platforms to sell more merchandise, create better artwork, and manage all your orders. We’re talking about connecting the powers of InkSoft, GraphicsFlow, and Printavo for a printing and shop management powerhouse.

Here’s how these three platforms will help you make the most out of DTF printing:

- InkSoft: Combine the short-run/short-turnaround capability of DTF prints with online stores. You’ll be able to provide a unique e-commerce solution for customers that need to promote and sell their merchandise quicker. This combo is perfect for scenarios like fundraisers, limited-edition apparel drops, or other customer stores that have an end date. InkSoft also gives you a quicker way to build and finalize proposals so you can move to production sooner.

- GraphicsFlow: GraphicsFlow’s massive art library is the perfect companion for DTF printing. Use the platform’s design ideas, fonts, and graphics to create professional, retail-inspired multicolor artwork for customers and then finalize the design with RIP software.

- Printavo: Use Printavo’s order management tools to make more of these small orders easier, making it more profitable for your business. You can also set up repeat business with customers interested in ongoing DTF prints.

DTF printing won’t necessarily replace anything that’s already on the market, but it’s a great option if you want more tools for short turnaround/low quantity orders with detailed customization. And if you combine it with the power of InkSoft, Printavo, and GraphicsFlow, you’ll be able to boost your bottom line and step up your order volume throughout the year.

Ready to pair the power of these three platforms with DTF printing? Schedule a tour today.

Take the Next Step

Learn how to take your business to the next level for less than $10 per day.

Comments are closed.